2. Deformation Sheet metal deforming procedures contain switching and processing sheet metal with no chopping it. Bending is One of the more essential forming processes, and it can be carried out utilizing a brake machine. A sheet metal organization can use this Instrument to bend sheet metal into V, U, and channels as much as one hundred twenty levels.

Standing seam roofing panels Possess a vertical ribbed appearance, Using the raised ribs concealing the fastening concerning the panels. Some panels may be snap-locked with each other, but Other people have to have special metal caps To lock the items in place.

Accounting for bend allowance is significant in understanding tips on how to bend sheet metal. This would ensure a lot more precise quantities making certain accuracy in completed goods.

(mm) that is necessary for these types of technical specs. Just about every Procedure demands a specific tonnage for each meter. This is also shown inside the desk. You could see that thicker materials and scaled-down within radii have to have extra power or tonnage. The highlighted solutions are recommended technical specs for metal bending.

Metal roofs are much easier to scrub than other components. They arise perfectly to a simple tension washing, whereas other roof varieties have to have specialty cleanings.

Roll bending is a way utilized to bend sheet metals into rolls or curved shapes. The method employs a hydraulic push, a press brake, and three sets of rollers to generate different bends or an enormous spherical bend.

In the event you style your bent sheet metal parts in CAD computer software that has a Specific sheet metal atmosphere, use it. It exists for a reason. When generating bends, it will require content specs into account. All this info is essential when building a flat sample for laser slicing.

To stay away from confusion, the rectangular hole might be on each side There lies a terrific Threat in making elements which might be Pretty much

Metal roofing provides improved durability and longevity than other roofing resources. These roofs are small-maintenance and proof against Serious weather conditions.

The incredibly high level of precision needed throughout the aerospace industry makes CNC machining an acceptable production course of action for that sector.

Although there are a number of factors to consider When picking a whole new roof, two of The main are the overall Charge and projected lifespan of every product. Find out how metal roofing compares to other roofing materials solutions by gauging both equally of those factors.

Pure tin roofs attained reputation following the Civil War and have become the most widely utilised material in U.S. property roofing. They’re less frequent given that more present day roofing products happen to be launched.

Aluminum – Yet another well-liked option for the producing sectors. It comes along with a wonderful power-to-body weight ratio. It also comes along with lots of features that aid website it meet many application prerequisites.

Given that the underside in the metal shingles or panels is sealed adequately, zinc can resist corrosion entirely.

Mr. T Then & Now!

Mr. T Then & Now! Scott Baio Then & Now!

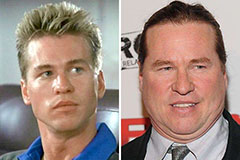

Scott Baio Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now!